Wohlenberg Polar Harris Perfecta Adast Scheneider Lawson Saber

|  |  |

and many more........

PROCUT is a high precision Guillotine Backgauge Retrofit Kit that can be installed on most automatic paper or metal cutting guillotines. Our control systems have years of proven history for accuracy, repeatability and reliability. They can be fitted to both new and old machines where positioning of the guillotine backstop is required.

- 32,000 Cut Positions

- Automatic Push Out

- Knife/Clamp/No Cut Control

- Air Table Control

- Name and Recall Programs

- Manual Electronic Jog

- Label Mode

Most importantly, it is easy to install and use! with the majority of installations taking less than a day to install.

Please view our list of kits here for PROCUT or visit our online shop:

We offer a number of types of retrofit guillotine backgauge control systems which offer 2 screen size options and a choice of DC servo motors and drives, AC Servo motors and drives or a standard AC motor with inverter as sometimes it is still possible to utilise the original motor.

PROCUT Guillotine Backgauge Control AC/DC Servo System:

This is a complete servo control system with all cables pre-made and with industrial connectors for easy, fast and reliable installation. The system is fully tested as a kit before leaving our factory to ensure all you have to do is mount the parts, plug the cables in and connect up to the electricity supply. The kit includes the servo motor with an encoder mounted at one end and a toothed pulley mounted on the output shaft. Installation of the motor is straightforward as we provide a mounting bracket with the motor which is then fixed to the back of the machine close to the leadscrew. TRM can also machine the leadscrew pulley providing we are supplied with the dimensions for the leadscrew and keyway.

Electrical installation is also straightforward and requires only mounting the controller and electrical cabinet, positioning the sensors using the brackets provided, then plug the cables to their corresponding socket on the electrical cabinet. If the Jog Wheel option has been purchased, this would then need to be mounted and plugged into it's corresponding connector. This then allows the user fine positional control of the cut position. An adjustment can then be stored as an offset to use on the next batch if required.

Software setup is generally straightforward as initial setup will have been done at the factory. All that remains for the user to do is set the size of the machine, the 'Play' for worn leadscrews, some motor settings may need changing depending on manufacturer used and finally calibrating to the machine. Once the easy to follow instructions have been completed, cut programs can then be entered and run or stored for future use.

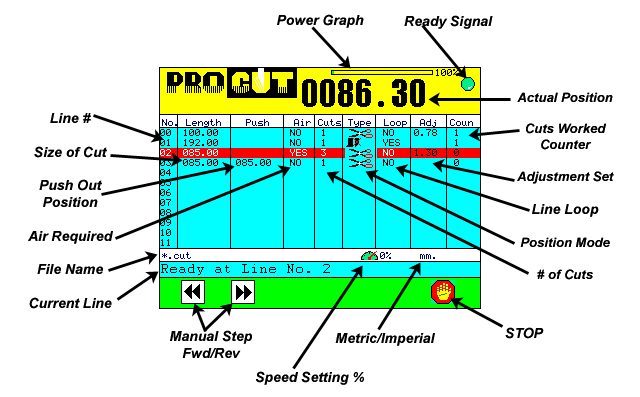

The following image shows the data available in the run mode for easy cutting.

If the mechanical parts of the machine are in good condition, the accuracy that can be expected with this system is 0.01 mm. A controller with electrical system and all cables are provided in this system to aid quick and easy installation with minimal parameters to set up. Full details of what's in the kit can be found on our page here.

Important safety note: PROCUT systems are not designed to override or interfere with ANY part of the cut control system. This must be maintained as per the machine design or to higher modern standards. If you are unsure, you should consult your local qualified maintenance technician for further advice.

|

|

|

PROCUT Guillotine Control for AC motor and Inverter:

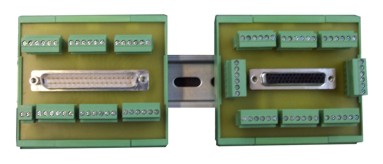

This system uses a Standard AC motor which is sometimes already installed in the machine. This is our most economic solution as shipping cost are lower than in the servo system but the installation requires more skill as the installer has to terminate some of the cables to the breakout boards and tune the inverter. Due to this the installation might take longer than the PROCUT System with servo explained above.

If the mechanical parts of the machine are in good condition, the accuracy that can be expected with this system is of 0.01 to 0.05 mm. Full details of what's in the kit can be found on our page here.

|

|